Introduction:

Phosgene, a vital chemical intermediate used in various industries, demands a thorough understanding of production processes and associated costs. This press release sheds light on the intricacies of Phosgene production cost analysis, offering valuable insights to stakeholders across sectors. From procurement resource assessment to raw materials requirements, this report provides a comprehensive overview to empower informed decision-making.

Explaining Procurement Resource Assessment in Phosgene Production Process:

A robust procurement resource assessment is fundamental to Phosgene production processes. It involves evaluating sources of raw materials, equipment, and utilities required for production. Factors such as reliability, cost-effectiveness, and sustainability are meticulously analyzed to ensure seamless operations. By optimizing procurement strategies, stakeholders can enhance efficiency, mitigate risks, and maintain competitive advantage in the Phosgene market.

Request Free Sample - https://www.procurementresource.com/production-cost-report-store/phosgene/request-sample

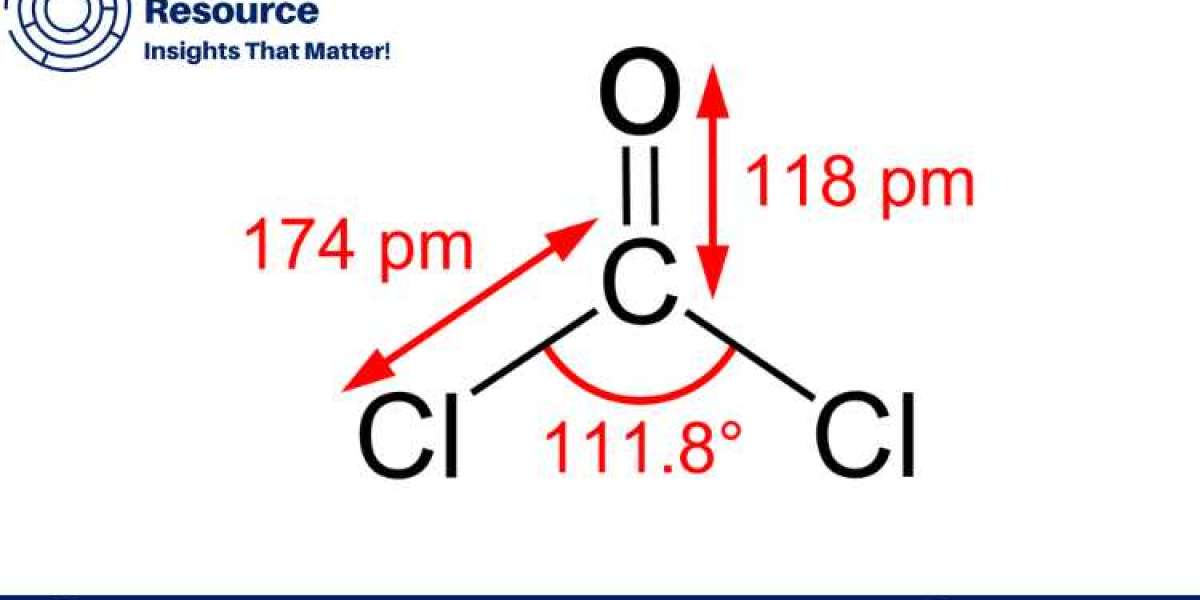

Defining the Product:

Phosgene, chemically known as carbonyl dichloride, serves as a key building block in the synthesis of various chemical compounds. Its versatile applications span industries such as pharmaceuticals, agrochemicals, and plastics. Understanding the properties, specifications, and quality standards of Phosgene is essential for manufacturers, ensuring compliance with regulatory requirements and meeting customer expectations.

Exploring Market Drivers:

The Phosgene market is influenced by a myriad of drivers, including industrial demand, technological advancements, regulatory policies, and macroeconomic factors. Rapid industrialization, burgeoning infrastructure development, and increasing focus on sustainable practices propel market growth. Conversely, factors like geopolitical tensions, supply chain disruptions, and environmental concerns pose challenges to market stability. By staying attuned to these drivers, stakeholders can anticipate market trends, capitalize on opportunities, and navigate uncertainties effectively.

Unveiling Raw Materials Requirements:

Phosgene production entails precise raw materials requirements, including chlorine gas and carbon monoxide. The quality, availability, and cost-effectiveness of these raw materials significantly impact production costs and process efficiency. Procuring raw materials from reliable sources, optimizing logistics, and implementing stringent quality control measures are imperative to ensuring uninterrupted production and maintaining product consistency.

Analyzing Costs and Key Process Information:

A comprehensive analysis of Phosgene production costs encompasses various components, including raw materials, utilities, labor, and overhead expenses. Cost structures vary depending on factors such as production scale, technology adoption, and geographical location. Key process information, such as reactor design, operating conditions, and process optimization strategies, further influence cost dynamics. By meticulously analyzing these factors, stakeholders gain insights to optimize production processes, enhance cost competitiveness, and maximize profitability.

Seeking an Exhaustive and Personalized Report:

In today's competitive business landscape, stakeholders seek comprehensive and tailored reports to drive strategic decision-making. An exhaustive Phosgene production cost report offers detailed insights, analysis, and recommendations tailored to specific business needs. From market trends and competitive landscape assessment to regulatory compliance and risk mitigation strategies, a personalized report serves as a valuable tool to substantiate business strategies and drive sustainable growth.

Conclusion:

In conclusion, the Phosgene production cost report delves into the intricacies of production processes, cost analysis, and strategic insights essential for stakeholders across industries. By understanding procurement resource assessment, market drivers, raw materials requirements, and cost dynamics, stakeholders can make informed decisions, optimize operations, and capitalize on emerging opportunities in the Phosgene market. An exhaustive and personalized report serves as a roadmap for success, empowering businesses to navigate challenges and achieve sustainable growth in the dynamic landscape of chemical manufacturing.

About Us:

Procurement Resource is an invaluable partner for businesses seeking comprehensive market research and strategic insights across a spectrum of industries. With a repository of over 500 chemicals, commodities, and utilities, updated regularly, they offer a cost-effective solution for diverse procurement needs. Their team of seasoned analysts conducts thorough research, delivering clients with up-to-date market reports, cost models, price analysis, and category insights.

By tracking prices and production costs across various goods and commodities, Procurement Resource ensures clients receive the latest and most reliable data. Collaborating with procurement teams across industries, they provide real-time facts and pioneering practices to streamline procurement processes and enable informed decision-making. Procurement Resource empowers clients to navigate complex supply chains, understand industry trends, and develop strategies for sustainable growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Amanda Williams

Email: [email protected]

Toll-Free Number: USA Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA